The world of manufacturing is constantly evolving. Sometimes we see the introduction of new technologies, while other times the change is seen with the existing ones.

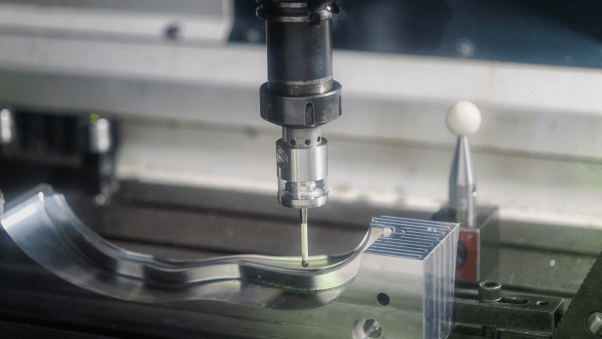

CNC machining is one of the established manufacturing technologies that is continuously evolving and getting better with time.

The best way to understand what has changed recently is not going through the technical details. Explaining in length something like new methods used in the placement of a CNC machining workpiece can be both exhausting and overwhelming.

Instead, the better approach is to go through what all the technological advancement has brought to CNC machining in general. That way, we can have a better understanding of the condition of CNC machining today, and even compare it to its state in the years before.

Here’s a rundown on all that makes CNC machining great, along with its few limitations. After all, no manufacturing process is perfect and CNC manufacturing is no exception.

Advantages of CNC Manufacturing

- CNC machines can operate continuously 24/7, 365 days a year without stopping, unless for maintenance purposes.

- CNC machines can replicate one program for as many times as needed and produce the same exact part with the same level of accuracy.

- CNC machines can be operated by operators that can undergo a speedy training and don’t have years of experience under their belt.

- CNC machines have plenty of safety protocols and features that prevent accidents.

- CNC machines can use advanced software solutions like PTC CREO.

- A single person can supervise multiple working CNC machines. In most cases, the operator will need to intervene when the cutting tool needs to be replaced.

- Modern design software can simulate the entire CNC milling process to its finest details. As a result, there is no need to create a model or a prototype. This saves both money and time.

- CNC milling is a very flexible process in which it’s easy to change sequences and other parameters on the go to adopt new changes.

Disadvantages of CNC Manufacturing

- CNC machines are still quite expensive compared to manually operated machines. Their costs are slowly going down.

- CNC operators can be trained fast and relatively easy. At least for the basic operations. That means less demand for trained engineers for operating centers and manually operated machines. This way, the old skills are slowly being lost.

- The transition from manually operated machines to CNC machines requires less human labor. The need of fewer people means higher unemployment.

- Regular maintenance is needed for smooth operations. That is costly and increases the production cost.

- Repairing a CNC machine can be a costly process.

In conclusion

Just five years ago, a list such as this would have been way different. It is thanks to technological advancements. From today’s point of stand, the biggest difference is that there are way fewer disadvantages than before. If we judge from what is in development currently, we can expect even fewer drawbacks in the upcoming years, both in performance and cost.