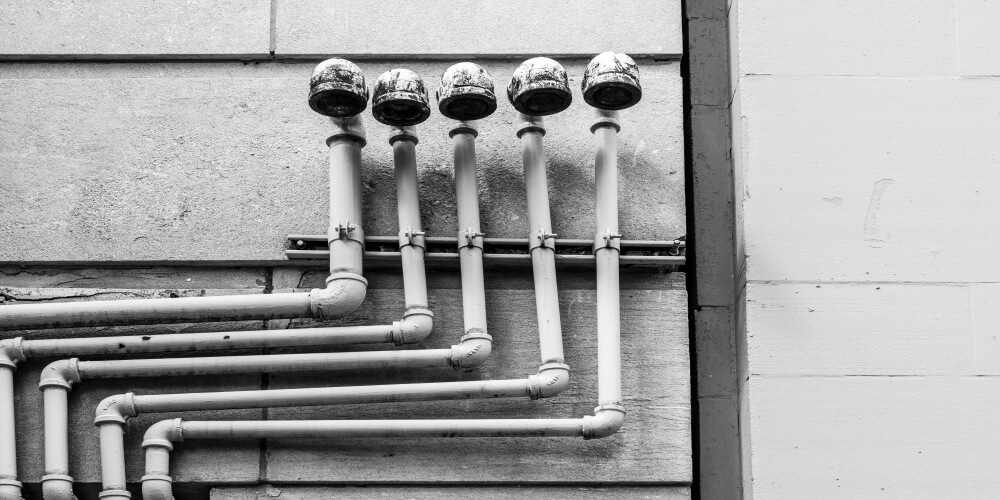

Tube fittings and connections form a myriad of systems that power and support many engineering projects. Each unit of stainless steel tube fittings was made with a clear goal in mind; to manufacture, transport, build, and conquer. To understand better, we are going to look into commonly used tube fittings.

In our basic outline, we will look through different terms; Interchangeable and intermixing steel tube fittings.

Interchangeable fittings

As the name suggests, these are parts of tubing systems that can be replaced. When the situation calls for interchangeability means that the part of stainless steel tube fittings needs a replacement, for instance, a broken tube. The whole part of the line will be retained, only a faulty section of the system is removed. This is an advantageous move since replacing the entire system may be expensive or cause inconveniences.

Intermixing fittings

Intermixing stainless steel tube fittings are compatible brands that work together in a tubing system to achieve the desired purpose. Blending is the safest and reliable way to attain simple connections.

Intermixing may be dangerous to the system if there is a slight deviation in some parts. This is the main drawback of such fittings. Before you consider intermixing, make sure you are conversant with the manufactures user manual.

Other common types of steel tube fittings are;

Elbows

The primary function of steel tubing is to support various structures where bends and corners are inevitable. Elbows are very helpful when manipulating around corners. They join steel tubes at different angles angle throughout the entire system.

Elbows are categorized according to the degree on which they arch; the most common types are 900 and 450.

Couplings

Coupling refers to joining two parts in the tuber section to form one continuous or lengthy tube. The collar is the most successful way to repair broken pipes.

Barbs

Barbs are used to connect flexible tubing to a horse. A typical male barb has three threads that attach to pipes, joining the two parts together. Combining male and female barbs forms a solid bond that prevents the horse from slipping out.

Valves

They are used to regulate the flow of liquid – preventing the backflow of fluid. Some of the major categories of valves are;

Isolating valves, it is used to disconnect some parts of the system temporarily. This is an essential approach convenient during the repair process, where a part of the system must be removed.

Isolation valves are a standby mechanism that will be used during emergencies. It’s essential to keep these valves well-furnished and in good condition for you don’t know when tragedy will knock.

Stainless steel tube fittings are strong and can withstand strenuous processes like a throttling valve. It operates under severe conditions where wear and tear are inevitable. Combining this steel accessory with an isolating valve will improve the system’s efficiency by allowing on site repairs while the system is on.

As a formidable and functional material, stainless steel tube fittings have various products, as named above.