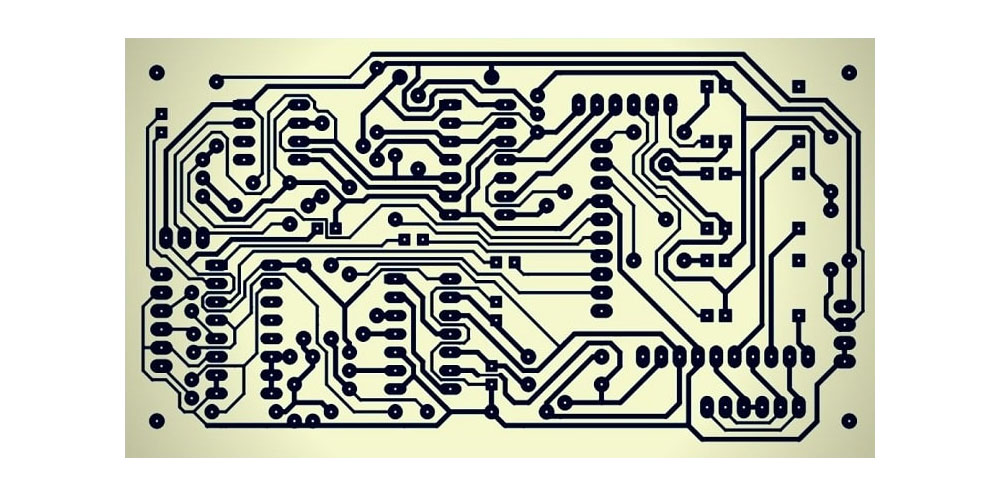

Every electronic device has a Printed Circuit Board. These boards provide a base and mechanical support for the connection of various elements. Before completing the actual object, a PCB prototype is made to represent it and give an idea of how it will look. There are different types of PCBs based on the kind of application. Each is designed differently also to suit the environment and serve its purpose. In this write-up, we delve into PCB uses.

How are PCBs Used?

PCBs play a big part in the functioning of gadgets. A lot is said about their designs to the development process, but how are they used? Below are some of the main PCB uses.

1. Day to day appliances

We often use these gadgets in our homes, places of work, or any communal setting. Such devices don’t require much power; hence the single-layer PCBs are ideal. These PCBs are cost-friendly, convenient, and very effective. They are also easy to replace or fix in case of an electrical problem. Appliances with such PCBs are smartphones, radios, microwaves, laptops, blenders, iron boxes, etc.

2. Large scale commercial production

Companies that produce goods on a large scale require very powerful machinery to ensure the process is smooth. These machines need high energy levels to run, and in return, they give off too much heat. PCBs with multiple layers come in handy as they can withstand high temperatures and pressure levels.

3. Medical Equipment

PCBs have also found a place in the medical industry. They are fitted in both simple and complex devices, depending on their structural design. An example of a simple machine is the pacemaker which functions with a single layer PCB while double or multiple layered PCBs fit the complex MRI machine. PCBs can also be used in devices that go inside the patient, like a tube. In such cases, flexible PCBs are the most ideal than the rigid type. In addition, PCBs within these machines help give proper accurate data, hence improving the medical industry.

4. Automobile industry

Over the years, new car models have emerged and are still being developed to date. They come with multiple features that vary from car to car and play different roles. Not only are they reliable and convenient, but they are also made for the driver’s safety. PCBs exist in elements like sensors and the engine system, which help the driver make essential choices like when to turn, change direction, or a route.

5. Protective systems

Since we cannot always have people physically handling all areas, security systems have been established to provide safety. These devices have PCBs that keep functioning for an extended period since security cameras stay on throughout. In addition, PCBs for outdoor gadgets are usually weatherproof to keep them in good condition and work as desired.

Bottom Line

All electronic devices possess a PCB, so their uses are vast. As technology advances, so is their use be it in commercial applications or everyday life. The increase in use is due to their affordability and effectiveness, qualities that every client would want for their device. Machines have become more reliable; hence life has generally become easier.