You are looking for extrusion services for low volume profiles? There are many companies in the market that you think may help handle the profile for you. But you may be surprised that they do not accept your prototyping order because they do not deal with low volume design. Not unless you are their esteemed customer but do you need to be a great customer in your initial stage? Of course not. 3ERP will give you the hand to start your production career through acceptance of your low volume profile services. There are various machining services such as CNC machining, turning, injection mold tooling among other services. Contact 3ERP for your tooling, extrusion and other machining services.

What is aluminium extrusion?

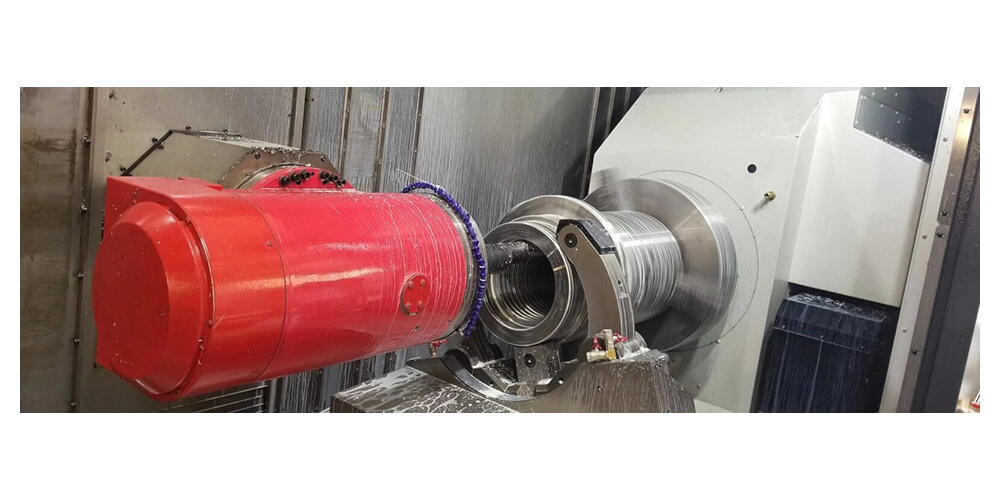

You have a taste of aluminium and maybe this is the only metal that you trust. To form the profile you need, you will need to have it go through the extrusion process. Aluminium extrusion is the process that aluminium materials are passed through a shaped opening in a die. The result is the profile of your design that you anticipated. You will then determine if the design is okay or need to be modified.

Ways to perform Aluminium extrusion

Hot Extrusion

This is an extrusion method that requires heat to facilitate the process of extrusion above room temperature. In this process of extrusion, you will likely have a large amount of aluminium converted at a faster rate and low pressure.

This is how hot extrusion works briefly:

The aluminium billet is first to cut into particular sizes. This billet is then heated to form a supple through temperatures of 300 to 600 degrees Celsius. It does not have to be liquefied. This heated supple is forced through a specifically shaped die with a pressure of around 10,000,000 pounds.

The extrusion has been formed, it is now allowed to cool before being cut to a customizable size according to your needs.

Cold Extrusion

In this process, your aluminium material will be pushed through the shaped die under room temperatures without any need for heating. It is recommended when you need to create huge parts with great finishing on them. This is a very cost-effective method you will not need to incur heat charges to shape the aluminium profiles and designs.

Standard aluminium extrusion profile

Many extrusion profiles can be used to make aluminium products. Have you seen the squire aluminium profiles, L shaped, J-shaped, F- shape, U- shape, T –shape, circular tubes among other standard aluminium extrusion profiles.

Apart from the standard profile types, There are standard series and sizes too. Such as

2020 Aluminium Extrusion (20mm X 20mm)

2040 Aluminium extrusion (20mmX 40mm)

8020 Aluminium extrusion (T- slot aluminium extrusion)

3030 Aluminium extrusion (30mm X 30 mm)

After extrusion you will receive all the other customized services that you will need such as polishing, fabrication, adding lathes through the machining services, from3ERP. You will receive these services at an affordable cost. 3ERP will always serve you at the lowest volume hence promoting your design dream.