Gaskets are used for sealing purposes for both industrial processes and other engineering works, such as car engine fluid systems. When fitted properly and selected appropriately, gaskets provide leak-proof sealing that can withstand high pressure, temperatures, or corrosion from chemicals. At Teflex Gasket Company, you get the luxury of choosing different designs of gasket elements and running through their properties of your product before making the purchase. Before ordering for one, the following are some of the determinants of the suitability of a gasket for your sealing needs in 2020:

Properties: Your gasket sealer should have the right properties that align with the conditions around your gasket sealed area. If the area is subjected to high temperatures, always go for gasket sealing made from materials that can withstand the heat without melting and contaminating the products or damaging other parts. A gasket made from a material that cannot withstand high pressure can easily cause industrial accidents when the machine bursts at the sealed area.

A gasket that freezes under cold temperatures can delay your production process leading to costly longer lead times. If the area requires cryogenic sealing, consider purchasing gaskets made from PTFE or graphite as they are flexible and can withstand extreme temperatures.

Existing rules and regulations: One of the areas that are easily overlooked is the existing rules and regulations. Most people assume that once gaskets are available in the market, it means they can be used globally. Such assumptions are usually costly as it may earn cost your processing plant money in the form of fines and reputational damage. Some of the gaskets available in the market today are made of asbestos.

The substance is banned in many jurisdictions due to health risks. Therefore, take your time to understand the legal landscape in your industry before shelling out your hard-earned money on gasket sealers. If you are specializing in food and drinks production, ensure that the gasket adhesive is safe.

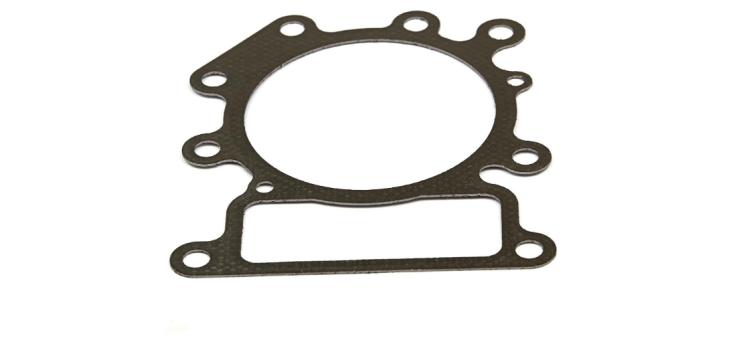

Flange design: The flange design of your gasket of choice is one of the primary determinants of its suitability for your sealing task. Flange designs are determined by the material used in making the gasket, the bolt holes, and the flange types. For the best sealing experience, always ensure that the gasket material matches with the surfaces to be sealed. Match the number of bolt holes on the gasket to the substance and ensure that the shape also aligns properly.

Cost: The suitability of a gasket is also determined by its cost. Always ensure that you purchase a gasket with a high return on investment. Depending on the scale of your sealing task, buying gaskets may require significant financial outlay. If the sealing job does not come with machine performance that equates to the cost, then your return on investment will probably be on the negative column.

Take-Home

When shopping for a gasket, always be intentional in the choices that you make. Arm yourself with information and facts on your needs and work with a budget to ensure that you get a return on your investment.