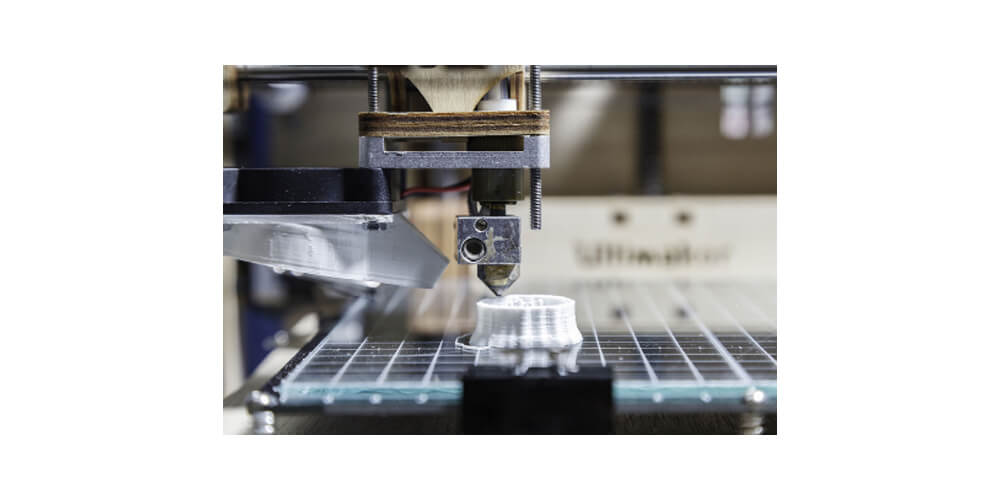

Rapid prototyping is the process of modifying machine parts using 3D computer-aided design. Due to a rise in the use of technology, a lot of innovations are taking place, and prototyping is one of them. https://industrial-statistics.com/effective-rapid-prototyping-projects/ shares additional insight.

How to Create Effective Rapid Prototyping for Projects

· Go for designs that can be modified with ease to save on cost.

· Communicate with prototyping suppliers in advance to help you choose the best design.

· Understand the need at hand to choose the best machining technology.

How Does Rapid Prototyping Work?

Additive manufacturing is the most used technology in the manufacturing process of prototypes, but other techniques such as molding, extruding, casting, and high-speed are used. Below are other affordable methods;

1. Subtractive manufacturing

Subtractive manufacturing, as the name suggests, is a process in which materials are removed from larger pieces until the prototype is created. With this process, one can design, prototype, and manufacture.

2. Compressive manufacturing

Compressive manufacturing is a process where materials are forced into the desired shape.

Materials Used in Prototyping

Due to the increased need for prototyping, different materials get produced daily. Engineers have several options. Below is a list of materials used in prototyping;

· Aluminum

· Rubber

· Copper

· Acrylic

· Stainless steel

· Silicon

· ABS

· Nylon

· Silicon

Types of Rapid Prototyping

In the creation of a prototype, there are different types used. Below are the most common types;

1. CNC Machining Rapid Prototyping

It is one of the most critical methods. This procedure doesn’t have specified materials to use since it can create parts from any content.

2. Stereolithography (SLA)

For this type, 3D printing is used. It is used in the manufacture of plastic prototypes. It is used in the production of components that get produced within a short period.No matter the shape; Stereolithography can create accurate prototypes. Prototypes made with Stereolithography can be machined since they are durable.

3. Selective Laser Sintering (SLS)

It is the most common additive manufacturing method. It is used in metal and plastic prototyping. In the creation process of a substantial part, 3D printing is used to heat powdered material used.

4. Fused Deposition Modelling (FDM)

It can be found in most 3D non-industrial desktop printers. It is cheap and easy to use, making it the best for low-volume production. Thermoplastic filaments get melted before a computer deposition program is used to lay them layer by layer. With time, the process has improved, making the best for product development.

5. Selective Laser Melting (SLM)

It is also known as powder bed infusion. It is a process used in the production of durable and complex parts. The parts produced using this process are used in industries such as medical, aerospace, automotive, and defense.

Pros of Rapid Prototyping

· With rapid prototyping services, one can change and improve the product depending on its performance.(read more at https://rapiddone.com/rapid-prototyping-services).

· Rapid prototyping is automated; therefore, it is cheap since less staff is needed to operate.

· The use of Computer-Aided Design reduces material wastage since all products use the same tools for prototyping.

Cons of Rapid Prototyping

· The end products are of low quality. Most machines used are inaccurate; the parts made don’t last.

· If the volume is large, the cost will be high.

Final Thoughts

For rapid prototyping, one must understand the process, materials, and types used to choose the best depending on their budget. Consider why you need rapid prototyping and, from there, make a choice.