Industries are looking to diversify from manual machines to the more efficient automated tools. Automated machines are quite advantageous for use in big enterprises due to the many processes being carried out simultaneously. One way in which some of these machines are made more efficient is via the use of planetary gearbox for load distribution.

Most gear box manufacturers design these gear systems with the requirements of heavy-duty industries in mind. The traditional gear systems are known to run into issues when subjected to heavy loading. Problems like broken gear teeth are not uncommon in such settings; this is why the use of planetary gear makes absolute sense. This article x-rays some of the vital industries where the use of planetary gearbox continues to prove handy.

Curved stairlifts

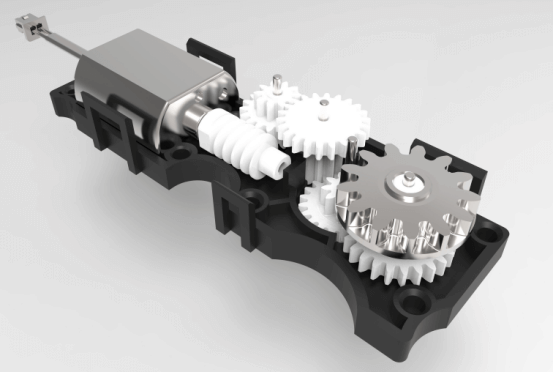

Curved stairs are simply stairs that have elongated bends and corners. Modern homes and office complexes usually use this stair type to save space and improve aesthetics. However, maneuvering such stairs could prove tedious for most people due to the need to go around corners. An innovative approach to moving around curved stairs involves the use of automated lifts. These stairlifts are attached to custom rails that run along the length of the stairs, and a button push sets you on your way. One of the main components of the stairlift is the custom planetary gear that’s designed to be compact and efficient. The planetary gear works in a way that noise is minimized while optimal efficiency is retained.

![]() Automated Guided Vehicles

Automated Guided Vehicles

There’s a gradual shift from crewed vehicles to automated vehicles that deliver the same level of performance. Apart from being more economical, the fact that these automated vehicles can work within enclosed spaces also makes them advantageous. Industries that make use of AGVs include; logistics and distribution companies, agricultural technology as well as medical supplies. Custom Planetary gears are used in generating much-needed torque in these crewless vehicles for top performance.

Conveyor systems

Large warehouses and other facilities make use of conveyor systems in their production lines. Some conveyor systems have an endless loop of carrying materials, and this goes a long way in the improvement of productivity. These conveyor systems are powered via the torque generated by custom planetary gears. Even though the gears produce vast amounts of torque, the noise produced is quite minimal.

Construction of machines

In the production of heavy machinery, there’s always a need to bend and roll metal sheets. To generate the massive amount of torque needed for this operation, the use of a custom planetary gearbox is often applied. The planetary gears are usually connected directly to hydraulic motors that turn the rollers seamlessly; this helps to improve productivity on the long haul.

Final thoughts

It’s no gainsaying that you’re always looking to increase the output of your machinery. There’s no better way to go about this than via the installation of custom planetary gears.