Rapid tooling has made everything easy and possible, especially enabling prototype, pre-production as well as full production tooling all being fabricated within greatly reduced time frames. Ideally, rapid tooling techniques are Rapid Prototyping that involves the RP-generated objects into the tool-making process.

There’re two major categories of rapid tooling with one category involving an indirect approach that uses RP master patterns in producing a mold. The other category is the direct approach, whereby the RP machine builds actual core as well as cavity mold inserts.

The most common rapid tooling types in prototyping include;

3D Printing

This is arguably the most popular method across the globe. In fact, it’s so mainstream that amateur level users even are capable of doing it at home. 3D printing method seems to be evolving without stopping any time soon, and it’s becoming even cheaper with the highest quality.

With the 3D method, molds are being created very fast and very cheap to make. Moreover, the devices that are used have an excellent range of handling intricate designs as well as angles. However, much is required to be done on the method of tolerances. Also, one can’t get several productions runs from the molds that are created with the 3D printing method.

Laser Sintering

Metal is not used only for rapid tooling via the traditional machining, but also can be used in creating a plastic injection mold, whereby metal particles can be fused together to make a solvent; a process known as “sintering.”

Sintering in rapid tooling is performed by spraying powdered metal to a laser beam that allows drawing of the shape of the mold. Several metals can be used in the process, including titanium, stainless steel, or cobalt chromium.

It’s one of the most precise, clean, and powerful manufacturing processes. Moreover, making the mold with the process allows you to have complete control over the transfers of heat, ejection times as well as clamping pressures. Also, printing cooling lines on your mold in making production cycles become faster and efficient.

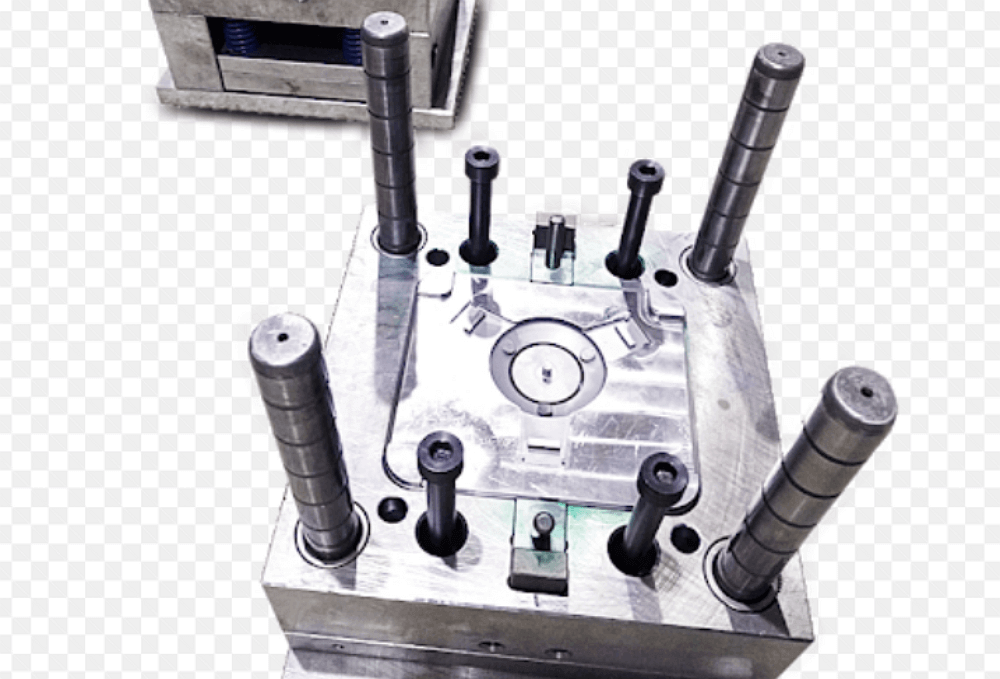

Traditional Machining

Rapid tooling can also be done through traditional machining. For instance, when it was first introduced, those companies that were building molds via traditional methods such as machining steel or aluminum started to increase speed to ensure that they also compete.

Rapid tooling was eventually used for every tool which could be quickly built, even those that could be created with traditional methods.

However, the most downside of the traditional rapid tooling method is geometry. For instance, if one looks to cut a cavity shape, then there’s a limitation by the cutter used, meaning that one can’t use a round cutter to cut a square corner.

Nevertheless, it should always be kept in mind that because one is capable of creating a mold using rapid tooling doesn’t guarantee to save a lot of time. The mold creation process is usually faster when compared with the traditional machining of aluminum or steel. However, it requires some finishing touches, which usually can slow the process down once you create the mold.