CNC Milling is a term that is although usually used in the manufacturing and industrial production parlance; it is gradually becoming part and parcel of common parlance amongst most business-minded people.

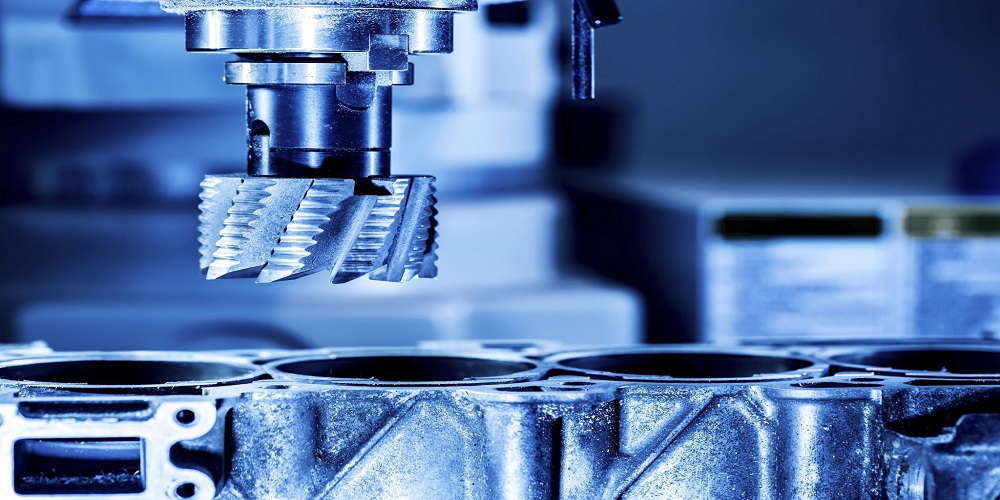

CNC milling can be defined as an automated method of manufacturing items through the use of pre-programmed computer software milling machines which control the movements of machinery to cut or drill parts to a mathematical accuracy. With the help of various milling parts, products can be CNC machined ranging from household items to military weapons amongst others.

Types of CNC Milling Machines

There are various types of CNC milling machines and they have their own different uses. The type of CNC milling machine to employ is dependent on the task sought to be achieved. What differentiates the milling machines from each other is the range of their cutting.

The various types of CNC milling machines are;

1. Two-axis milling machines

These are milling machines that can cut holes horizontally and vertically but only in one direction. In other words, it can cut parts in the horizontal and z axes.

2. Three-axis milling machines

These are milling machines that can cut holes vertically in any direction and horizontally in one direction. It adds the vertical axis. This is a fairly common form of CNC milling machine used. It is recommended for flat surfaces

3. Four-axis milling machines

These milling machines can perform more complex tasks because they add the ability to rotate the horizontal axis and gives a lot of latitude to cutting options.

4. Five-axis milling machines

These machines allow for the rotation of both the horizontal and vertical axes in multiple directions. This is the best milling machine because it can shape up or cut items in almost any shape you dream up.

Other variants of CNC Milling machines include;

- Horizontal Mill

- Vertical Mill

- Knee Mill, amongst others

CNC Milling- How it works

When a part is to be manufactured by CNC Milling Machining, the cuts that are necessary to make the product or item manufactured accurately are pre-programmed into the computer using software known as computer-aided design (CAD) model or computer-aided manufacturing (CAM) software.

The CAD model is then converted into a CNC program. This is to ensure that it is compatible with CNC Milling machine software to enable the machine to follow the instructions as already written in the software. The CNC Machining program is popularly known as G-code

The operator will then set up the machine to ensure it is ready for work by affixing all necessary parts to the machine spindle and also by putting the material/item that needs to be shaped on the work surface.

After that, he will run the CNC program and the machine will then cut the shape to the pre-programmed shape in the computer program.

Things That Can Be Made With CNC Milling

Most things can be made with CNC Milling. They include;

- Wood furniture

- sculptures

- Road signs

- Toys etc.

Conclusion

CNC milling is essential in achieving the manufacturing rates that are needed for the efficient utilization of resources. This article seeks to explain the subject matter and also illuminate the minds of readers that are curious about the utility of CNC Milling and how it can be harnessed.